This post is also available in: 简体中文 (Chinese (Simplified))

Rolling papers will be presented by Primetals Technologies specialists at the ESTAD Congress covering the topics of plate rolling, hot-strip rolling, cold rolling and long rolling.

Adaptive Eccentricity Compensation for Rolling Mills

Principal author: Andy Maierhofer

Paper number: 249

Keeping strip thickness within narrow tolerances is particularly important to ensure good strip quality, also at high rolling speeds. The thickness variations at the mill exit occur not only due to incoming strip variations and the forward slip effect that influences the tension, thickness variations are also caused by eccentric rolls as well as coil eccentricities. Roll eccentricities are the result of various factors that include non-uniform thermal expansion of the rolls, grinding inaccuracy or asymmetrical adjustment of the bearing roll shells via drive keys with the result that each roll causes oscillations with an eccentricity frequency. Coil eccentricities are caused by the beginning of the metal sheet on the mandrel, followed by wrapping with the next strip layers. A rapid diameter change of the coil occurs at this point, and hence tension oscillations in the strip are induced with each rotation of the coil. These tension oscillations lead to periodic thickness defects of the strip.

Utilizing an adaptive algorithm, it is possible to eliminate nearly the entire eccentricity oscillations of rolls and coiler up to their third harmonics. The new Roll Eccentricity Compensation (REC) as well as the Coil Eccentricity Compensation (CECO) algorithms were developed using automated code-generation techniques based on Matlab/Simulink. This innovative development process, first utilized at Primetals Technologies, speeds up the controller implementation process significantly and at the same time increases reliability.

Trendsetting Basic Automation Solutions for Rolling Mills

Principal author: Andreas Mantel

Paper number: 304

Today’s challenging markets require producers to permanently improve and modernize their plant operations, and this includes basic automation systems. New concepts such as Profinet and Profisafe – easy-to-use and intuitive HMIs – and powerful closed-loop controls, combined with decades of proven know-how, are the fundamentals of the innovative basic automation system. Standardized scalable hardware and modularized software secure investments today and tomorrow, and enable notable productivity increases to be achieved. Such features are the key for an optimal solution, whether for a partial or even complete automation exchange.

The innovative basic automation concept for rolling mills is introduced with special attention placed on virtualization of operational equipment. This contributes to hardware standardization, server consolidation and independency of operating systems.

Functional Enhancements to Improve the Rolling Process in Plate and Steckel Mills

Principal author: Dr. Matthias Kurz

Paper number: 223

Since 2002, Primetals Technologies has commissioned more than 20 plate and steckel mills worldwide in close cooperation with its customers. On the basis of the extensive knowledge acquired, process automation has been enhanced and state-of-the-art, model-based functionalities have been developed to provide customers with optimized solutions to boost their business. Fully automatic thermomechanical rolling using modern physical models and intelligent sequencing strategies achieves an optimum grain refinement and thus improves the mechanical properties of rolled plates. Monitoring and modeling of the material temperature as a function of thickness in combination with the advanced process automation of the cooling sections enables tighter control of the mechanical properties of the final plate/strip and an expansion of the product portfolio to include, for example, X70 and X80 grades. The novel profile and flatness strategy that was developed by Primetals Technologies relies on physical modeling, which enables large reductions to be taken without risking poor flatness. Head and tail tapering – based on process- dependent force deviations during thread-in/thread-out – significantly reduces the load impact to the mechanical equipment. Introduction of model-based roll-alignment control has been proven to be a key factor for camber- free rolling as it allows a significant increase of throughput and rolling stability to be achieved. Advanced pacing strategies within the mill area and cooling-bed charging optimization provide an optimized material transport throughout the entire production chain, including speed- optimized crop-shear sequencing. In this paper, the operational features and performance of these and other solutions are described..

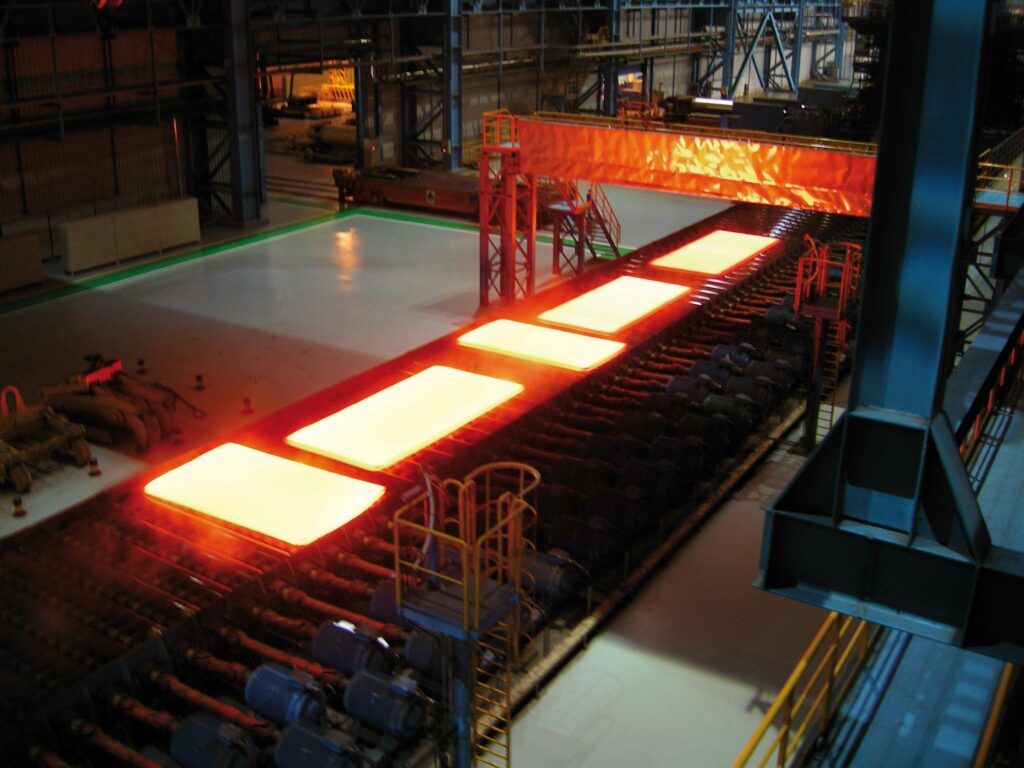

Mulpic – The Most Powerful Metallurgical Tool in Modern Plate Production

Principal author: Sandip Samanta

Paper number: 195

The inline accelerated cooling process has become a standard solution for modern plate mills in order to produce higher-strength steels and higher-value grades. Since 2002, Siemens VAI has commissioned numerous Mulpic (multi-purpose interrupted cooling) cooling systems at plate mills throughout the world. The high cooling accuracy and temperature uniformity of plates processed with Mulpic – in combination with intelligent sequencing, accurate speed and flow control and a fully optimized cooling model – have made Mulpic the metallurgical tool of choice for plate cooling.

Until recently, all of these installations were standard Mulpic machines of 24 m in length. However, with low capital-investment levels, plate producers are looking for performance improvements by adding high-flow-density headers in front of existing laminar cooling sections. This hybrid configuration provides several challenges for process control as well as engineering. The challenges and benefits associated with such a hybrid cooling machine are discussed, as well as the steps taken to ensure an optimum design, rapid installation, fast start-up and excellent results.

Process Know-how – The Key to Unlocking the Mill’s Hidden Potential

Principal author: Andrew Harvey

Paper number: 198

During the first decade of the 21st century, there was a boom in new plant installations and steel production. Primetals Technologies alone installed and commissioned 18 plate mills and 30 aluminum mills. Since market conditions changed virtually overnight in 2008, producers have been seeking to maintain profits by improving production processes in installed mills. On the basis of its mill expertise and process know-how combined with its metallurgical skills, Primetals Technologies has supported several established plate manufacturers to reduce costs, increase quality and enhance production. A number of these improvements are discussed in this paper.

One of the significant improvements was in the production of normalized rolled steel plates, which eliminated the need for subsequent heat treatment of these plates. The burden on the heat treatment line is reduced, and overall throughput for high-value plates is increased. Another example is the improvement of thin plate flatness off the mill to reduce the amount of cold leveling required. This reduces costs and broadens the customer’s market portfolio. Primetals Technologies worked with another plate producer to improve thickness accuracy and yield, reducing the number of rejected plates in one month by more than 50%. Recent work with an aluminum plant has required changes to rolling schedules, resulting in a doubling of the achievable rolling speeds. Although different customers have different problems, the considerable process know-how and experience of Primetals Technologies helps producers to optimize their mill performance.

Through-process Leveling Technologies to Meet Ever-increasing Demands for Final Plate Flatness

Principal author: Sebastien Maillard

Paper number: 194

End users of steel plate are looking for high-strength plate with better flatness and minimum residual stress in finished products. Technologists are facing tremendous challenges to design machines that can meet those requirements with a wide variety of plate thicknesses, widths and strengths. The recent develop- ment of process routes in plate manufacturing with sophisticated inline cooling such as the Mulpic machine has further complicated leveling requirements. To strike a balance between these design requirements and the investment, Primetals Technologies has developed two solutions to cover current and future process demands. With a specific focus on thin and medium gauges, the first of these solutions has been designed where flexibility is brought in different roll configurations through the positioning of selected rolls actuated by dedicated wedge assemblies in a flexible single cassette. For thick plate leveling, different roll configurations are applied through the use of specific cassettes with different roll diameters and pitch, achieved by an innovative spindle support adaptive design. For both solutions, the intelligent control system along with an adaptation algorithm based on observable neural network ensures precise control of roll gaps along with individual torque and speed control of each motor, which results in best flatness and minimum residual stress in the final leveled product. When implementing these solutions into existing or new plants, decisions on design selection are made considering the overall manufacturing path for the related product mix. Examples of strategies to master flatness are highlighted, considering the various stages of plate manufacturing from rolling, cooling and shearing.

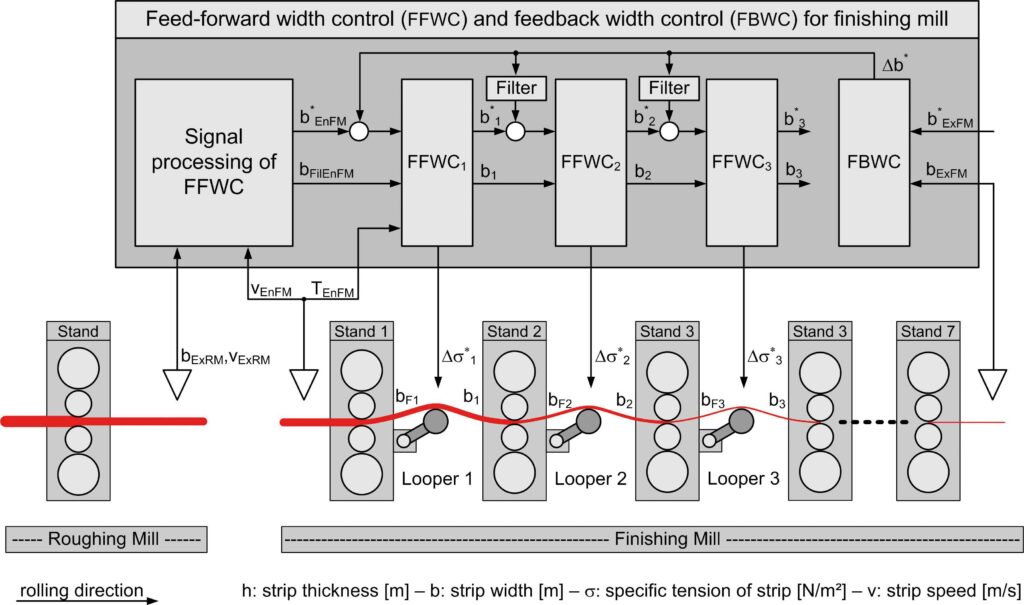

Model-based Width Control in Finishing Mills

Principal author: Daniel Kotzian

Paper number: 224

Reduction of strip-width deviations and the avoidance of overwidth and below-minimum widths after the finishing mill are key challenges for today’s basic and process automation systems in hot-strip mills. Logically, the strip width in a hot-strip mill is mostly influenced by pressing or vertical rolling of the strip in the roughing mill. Width deviations after the finishing mill arise from width deviations in front of the finishing mill or from a width spread anomaly that takes place inside the finishing mill. The behavior of width spread in a finishing mill depends on effects in roll bite and on the creep deformation between the stands. As a result, the width spread in a roll bite is influenced by, for example, thickness reduction, back tension and change of the strip-crown ratio. The creep deformation between the stands depends on, among others, yield stress, strip temperature, specific tension, distance between stands and strip speed. It was recognized that tension can be used to manipulate the strip width in the finishing mill. Entry width deviation is compensated by a feed-forward width control. Residual exit width deviation is compensated by a feedback width control. Moreover, the model- based feed-forward width control considers effects of width spread in the roll bite and the creep deformation between the stands. The concept and test results of model-based width control are described in this paper.

Enhanced Technologies for Rolling Advanced High-Strength Steel Grades in Hot-strip Mills

Principal author: Julian Thoresson

Paper number: 293

New market opportunities in the area of advanced high-strength steels (AHSS) – including dual-phase, martensitic, complex-phase, transformation-induced plasticity (TRIP), and highest-strength pipe grades – are discussed in this paper. When attempting to produce these steel grades, existing mills often reach their limits in terms of power and flexibility.

Primetals Technologies offers a number of solutions for cooling and coiling AHSS grades in hot-strip mills. For example, the recently developed Power Cooling solution combines the advantages of laminar cooling and pressurized high-power cooling with high cooling rates to enable more flexible cooling strategies to be applied. High-strength and thick-gauge materials are reliably coiled using the Power Coiler from Primetals Technologies. Fully integrated mechanical equipment design and sophisticated process-optimization models are decisive for the reliable and economic production of high-strength steels for a wide range of strip dimensions. Possibilities for finishing mill equipment upgrades in addition to other aspects related to cooling technology and the coiling area are also presented.

Real-time Phase-transformation Control in Hot-strip Mills

Principal author: Peter Hunt

Paper number: 199

Following the successful development and site trials of the electromagnetic spectroscopy (EMSpec) sensor, the focus has now moved to integrating multiple sensors into the cooling model to allow hot-strip mills to produce higher-grade steels. The EMSpec sensor employs the principle of measuring the complex impedance of the target steel over a range of frequencies, which in turn varies with the transformation fraction of the steel. For the successful production of dual-phase, TRIP1) and TWIP2) steels, better control of the cooling regime is required. The use of surface temperature measurements is not sufficient to achieve the desired microstructure. The EMSpec sensor can directly measure the percentage transformation of the steel in the cooling area, typically in the accelerated water-cooling zone. The sensor is engineered to work in this harsh environment. By enhancing the mill model to predict the transformation profile in the cooling zone, the EMSpec sensors can be used as feedback to control the cooling rates to achieve the desired microstructure.

A full-scale implementation of the real-time transformation control has been installed at a large European quality-steel producer to show the benefits of such a system. A total of three EMSpec sensor heads have been installed between the exit of the finishing mill and the entry coiler to allow the mill to be controlled to produce these high-grade steels commercially. The number of heads can be tailored to suit the specific application. The technology of the EMSpec sensor will be evaluated in an endless strip production mill and in other heat-treatment processes, such as annealing furnaces.

1)TRIP = transformation-induced plasticity

2)TWIP = twinning-induced plasticity

Wedge and Camber Control

Principal author: Dr. Matthias Kurz

Paper number: 226

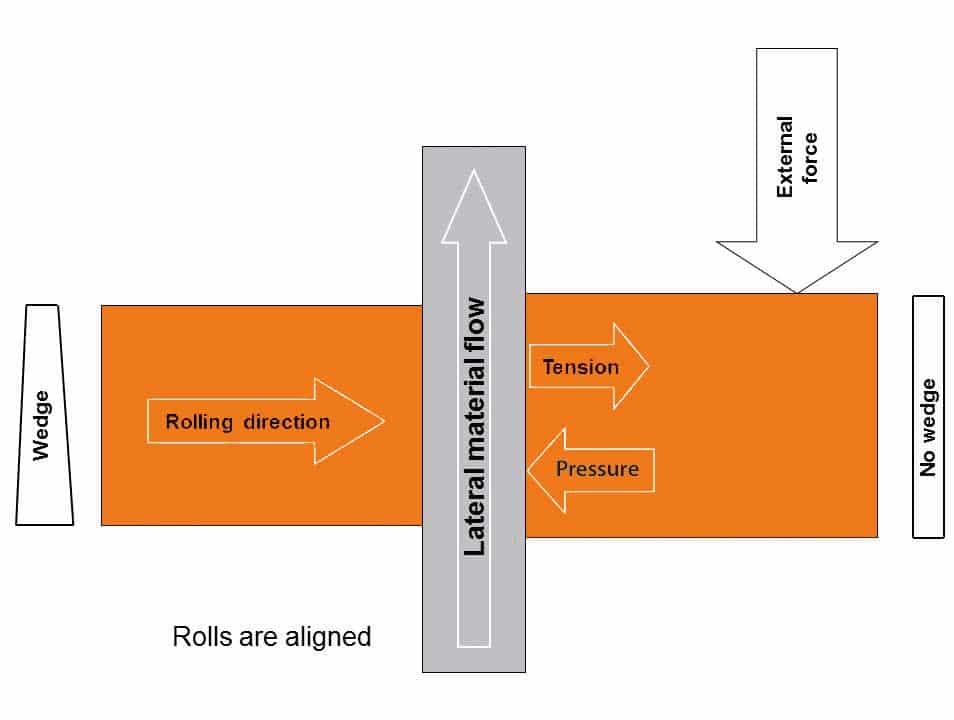

Reducing wedge without causing camber is a big challenge for today’s process-automation systems in hot-strip mills. Modern, so-called camber-free rolling systems apply cameras to swivel mill stands in roughing or finishing mills to minimize the lateral curvature (camber) of the rolled strip. Hence, all shape errors on the slab – initial camber or wedge – are transferred into a wedge on the final strip. This resulting wedge has to be accepted if no additional actuator is employed. This paper shows that lateral forces acting on the strip can induce lateral material flow in the roll bite. Furthermore, an automation scheme is presented that allows wedge to be reduced in a roughing mill stand without generating camber. Therefore, camber is fully decoupled from wedge, and roll tilting in the roughing mill stand can be used to control the wedge in the rolling process. A slab-to-slab control algorithm is presented using the measured wedge of the finished strip as input and the tilting of the roughing mill stand as the actuator. As a key to success, Primetals Technologies applies the edger to induce the required lateral forces in the upstream passes. Because only equipment that is available anyway is applied, no further investment in hardware is required to benefit from this automation scheme.

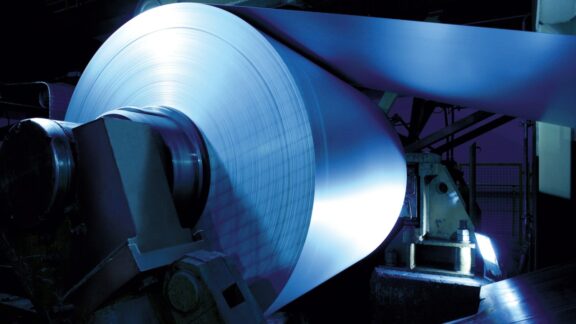

Elimination of Third-octave Mill Chatter Vibration in Cold Rolling – First Successful Pilot Installation

Principal author: Georg Keintzel

Paper number: 296

For decades, engineers have investigated the origin and elimination of third-octave mill chatter. Up until now, only chatter-monitoring systems have been successfully deployed, and for certain products, mills are often forced to operate at far lower speeds than the mill design would actually allow.

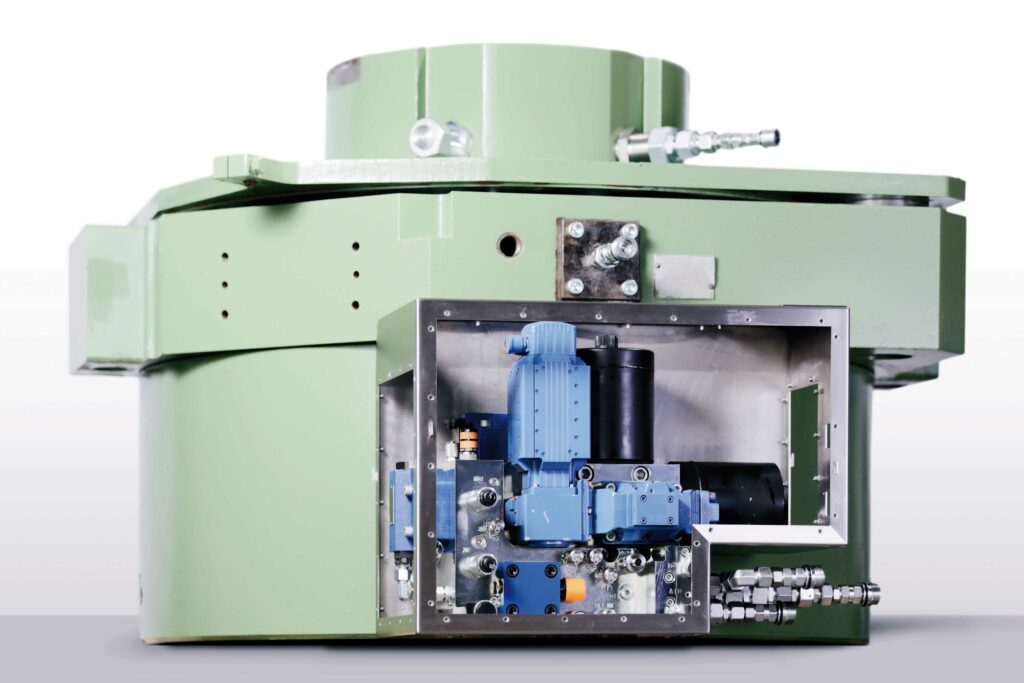

As the leading supplier of vibration consultancy service and solutions, Primetals Technologies has developed a unique solution for active vibration damping in order to eliminate third-octave mill chatter. The hydraulics-based system known as ChatterBlock Control has been successfully implemented for the first time. Third-octave mill chatter, typically occurring in a frequency range between 90 Hz and 150 Hz, is a self-excited vibration phenomenon that normally takes place in the final stands of tandem cold-rolling mills. It can produce significant gauge variations, strip defects and even cause strip breakage. This phenomenon severely limits mill productivity.

ChatterBlock Control was first installed on a 5-stand tandem cold-rolling mill where its effectiveness in suppressing third-octave mill chatter was confirmed. The technological solution and impressive results of this first industrial implementation are described in this paper.

The New 4-Roll Sizing Mill: Evolution of Bar Sizing

Principal author: Marco Langé

Paper number: 214

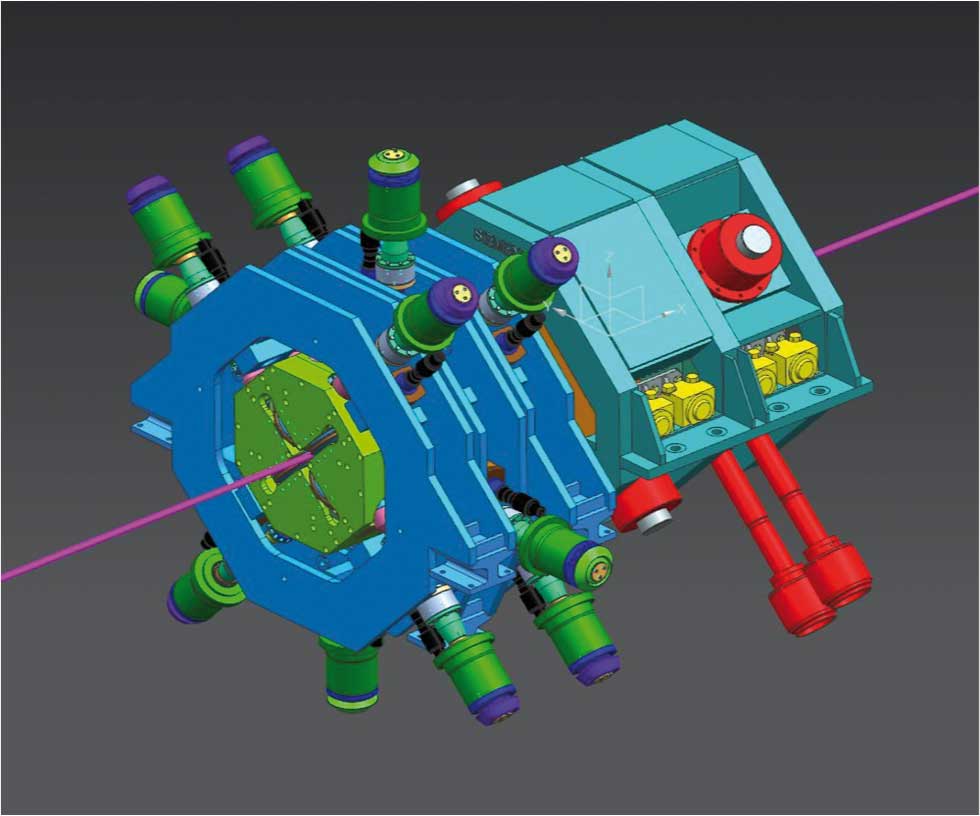

Primetals Technologies has developed a new 4-roll sizing mill to improve product quality and productivity of mills that roll high-end steels, such as engineering and stainless grades. This solution for precision rolling, which has been validated in experimental tests, was developed using modern numerical modeling techniques. The applied finite element analysis (FEA) technique is based on DEFORM 3D, which enables a detailed investigation of various rolling process parameters to be performed. This tool is enhanced by subroutine models that are derived from experimental results. This helps to identify the parameter’s subset, which optimizes the FEA prediction and leads to the best course for technology development.

Among the main advantages of 4-roll configurations are the improved accuracy of roll gap adjustment due to the high rigidity of the mill; the wide range of dimensions that may be rolled within tolerance without changing the groove; the negligible spread deformation that simplifies the dimensional control; and the improved metallurgical issues through the control of recrystallization and grain growth.

World’s First Application of the New idRHa+ Rail-hardening Technology at the Baogang Rail Mill in Baotou, China

Principal author: Federico Pegorin

Paper number: 283

Heavy-haul and high-speed railways call for long rails with precise linear tolerances and increased resistance to wear and rolling contact fatigue. This drives the development of new rail grades as well as improved manufacturing processes. In late 2013, the installation of the world’s first application of a breakthrough technology for rail hardening commenced at Baogang Iron & Steel (Group) Co. Ltd., one of the world’s leading rail producers. The Injector Dual-phase Rail Hardening (idRHa+) system was jointly developed by Primetals Technologies and the Italian technical center Centro Sviluppo Materiali. idRHa+ provides tailored inline cooling protocols, which serve to obtain an accurate fine-pearlitic microstructure and hardness distribution across the rail crown. With a unique level of flexibility, it can process more than 150 t/h of rails in a wide range of sizes, grades and standards. The design of idRHa+ is based on thermal, mechanical and metallurgical models, validated by experimental trials in an industrial pilot unit. During 2014, the system was commissioned at Baotou Rail Mill No. 2. This paper presents an overview of the key concepts behind idRHa+, as well as the progression of its commissioning and testing for several rail grades. Ramp-up to consistent industrial operation is also discussed.