TPO

Metals Magazine ISSUE #06 (Mar 2018)

Innovation and Technology for the Metals Industry

ISSUE #06 (Mar 2018)

The Smart Plant of the Future

ISSUE #06 (Mar 2018)

The Smart Plant of the Future

Christchurch: Shaping the World of Tomorrow

Overcoming Bottlenecks in Steelmaking with an AOD Converter

Feature Topic

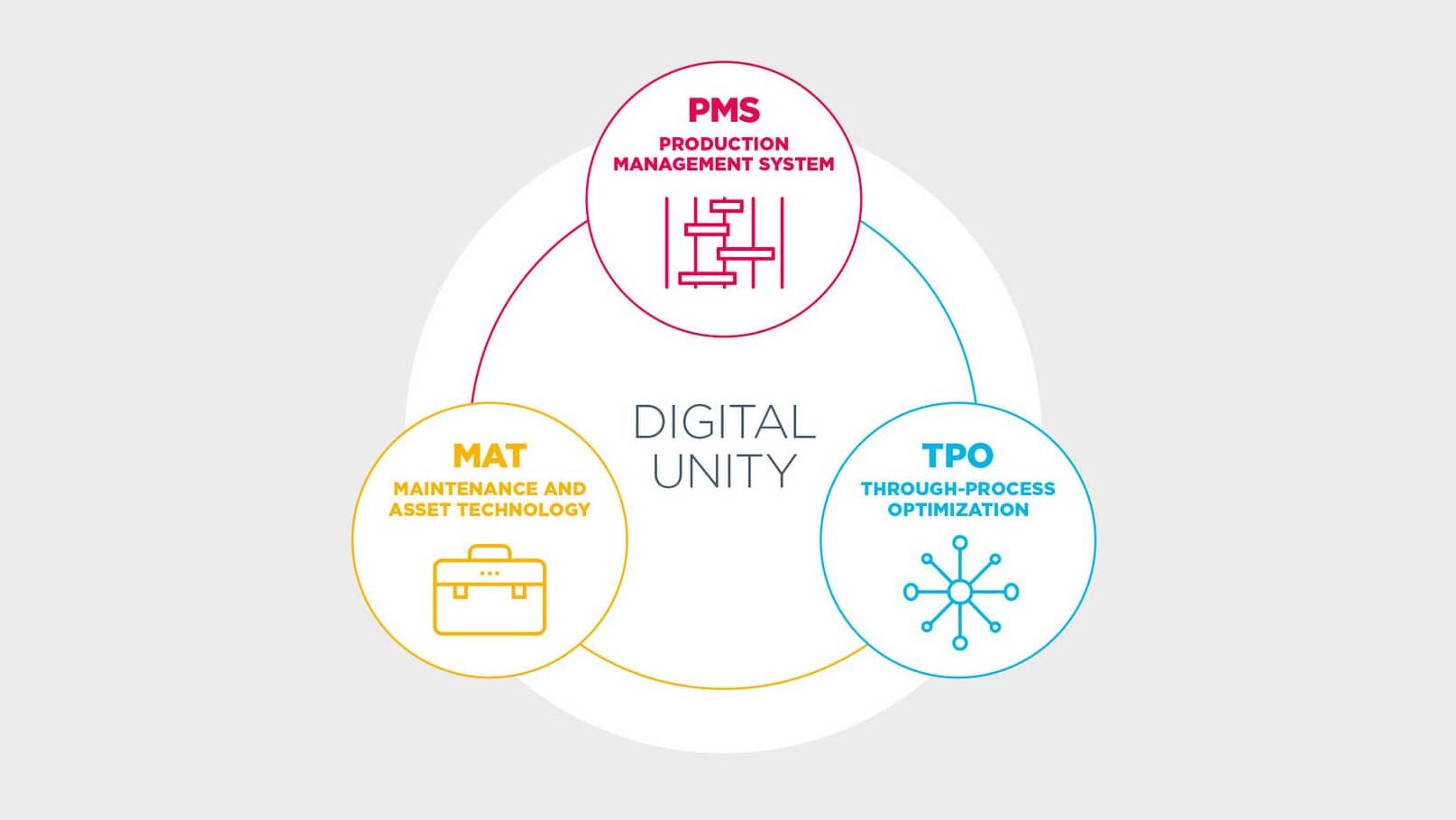

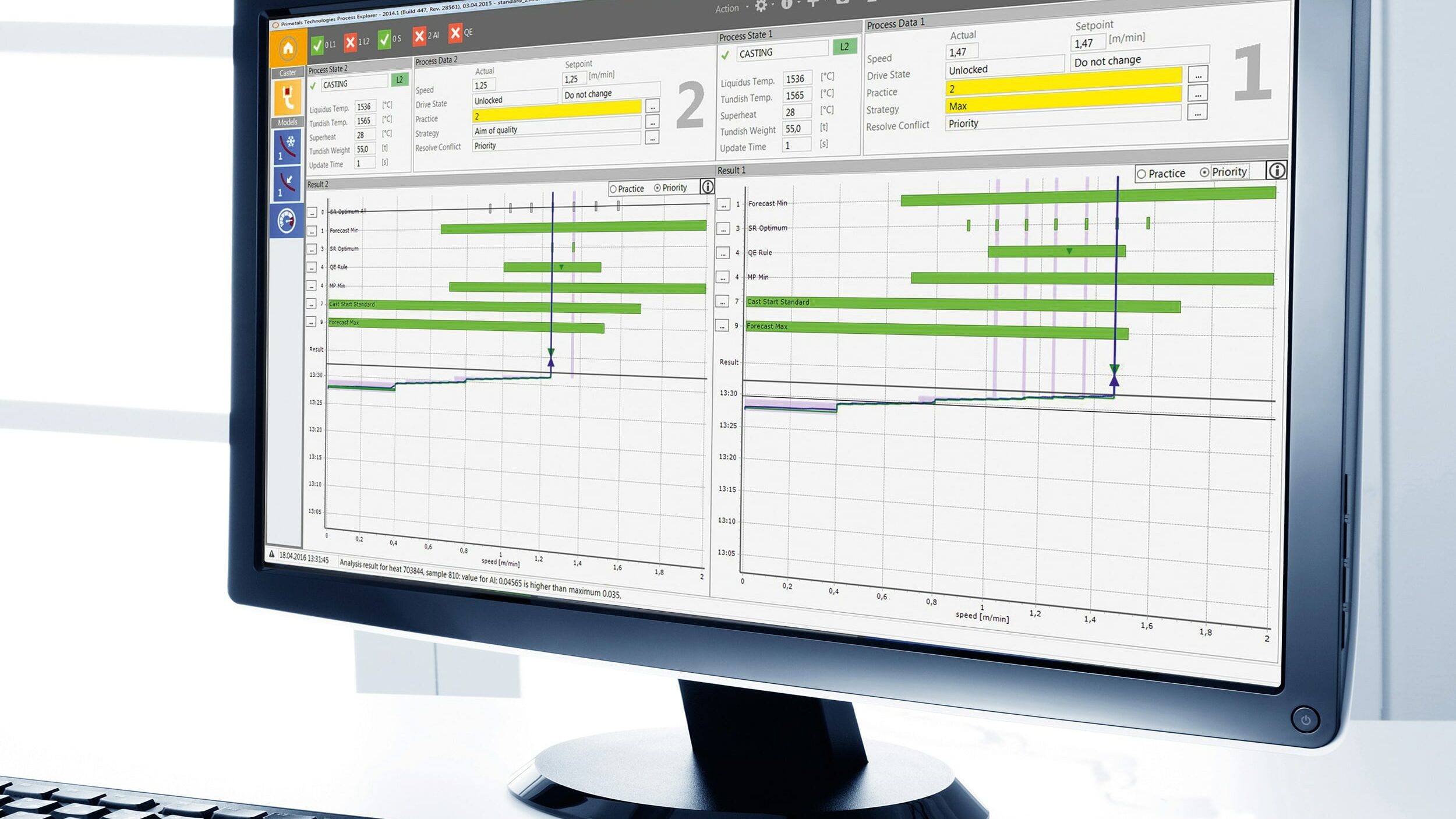

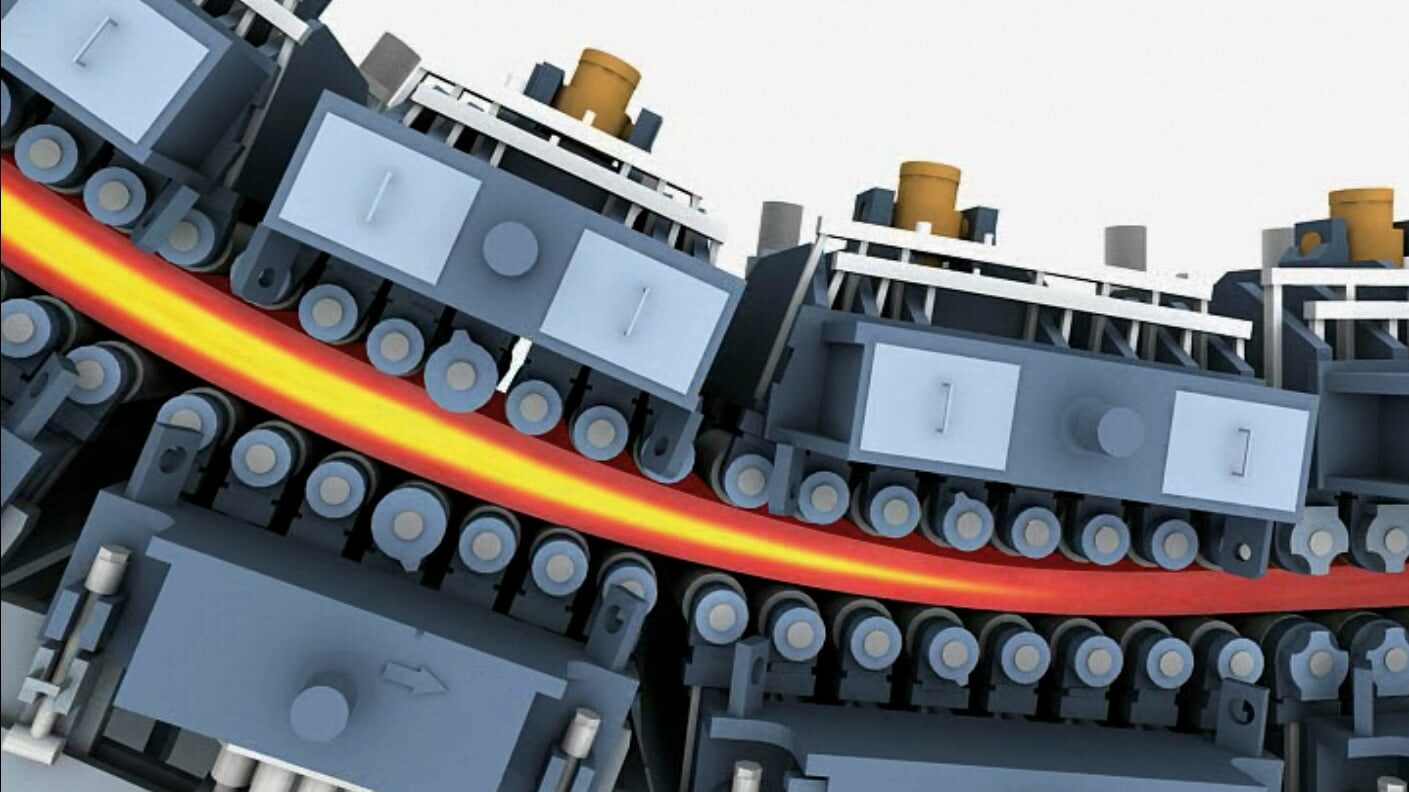

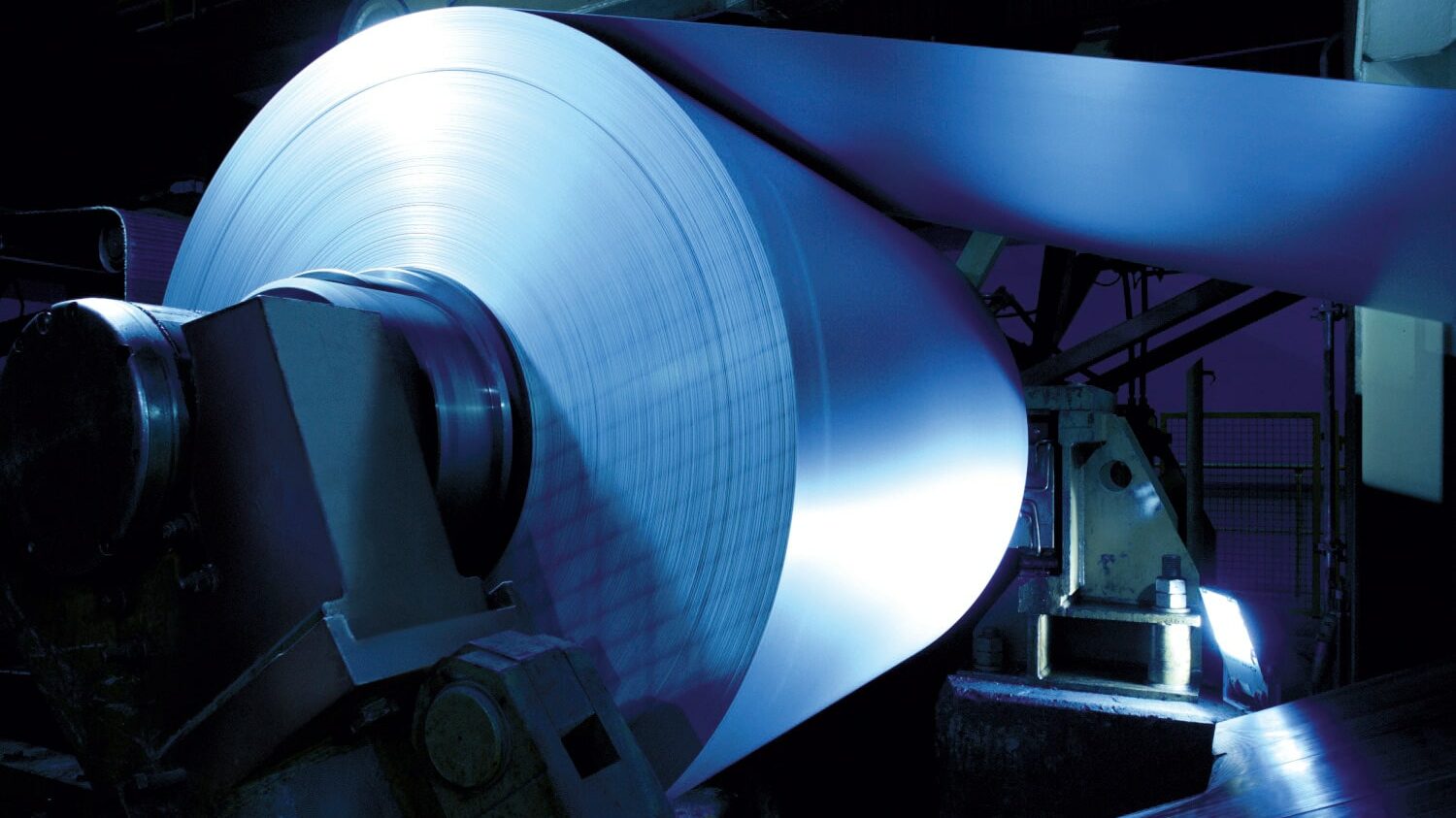

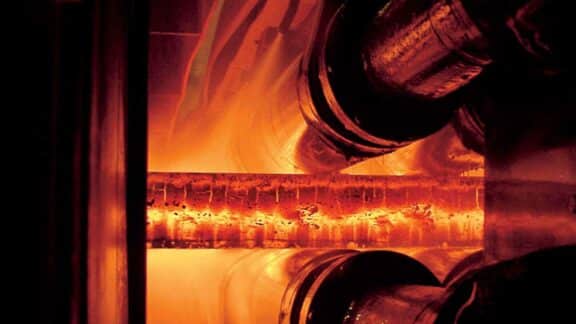

THE SMART PLANT OF THE FUTURE

THE FUTURE OF STEEL PRODUCTION IS BASED ON THE “INTELLIGENT ORCHESTRATION” OF ALL EQUIPMENT. WE TAKE A DETAILED LOOK AT HOW TO ACHIEVE IT.

Read more Company Locations

Hiroshima

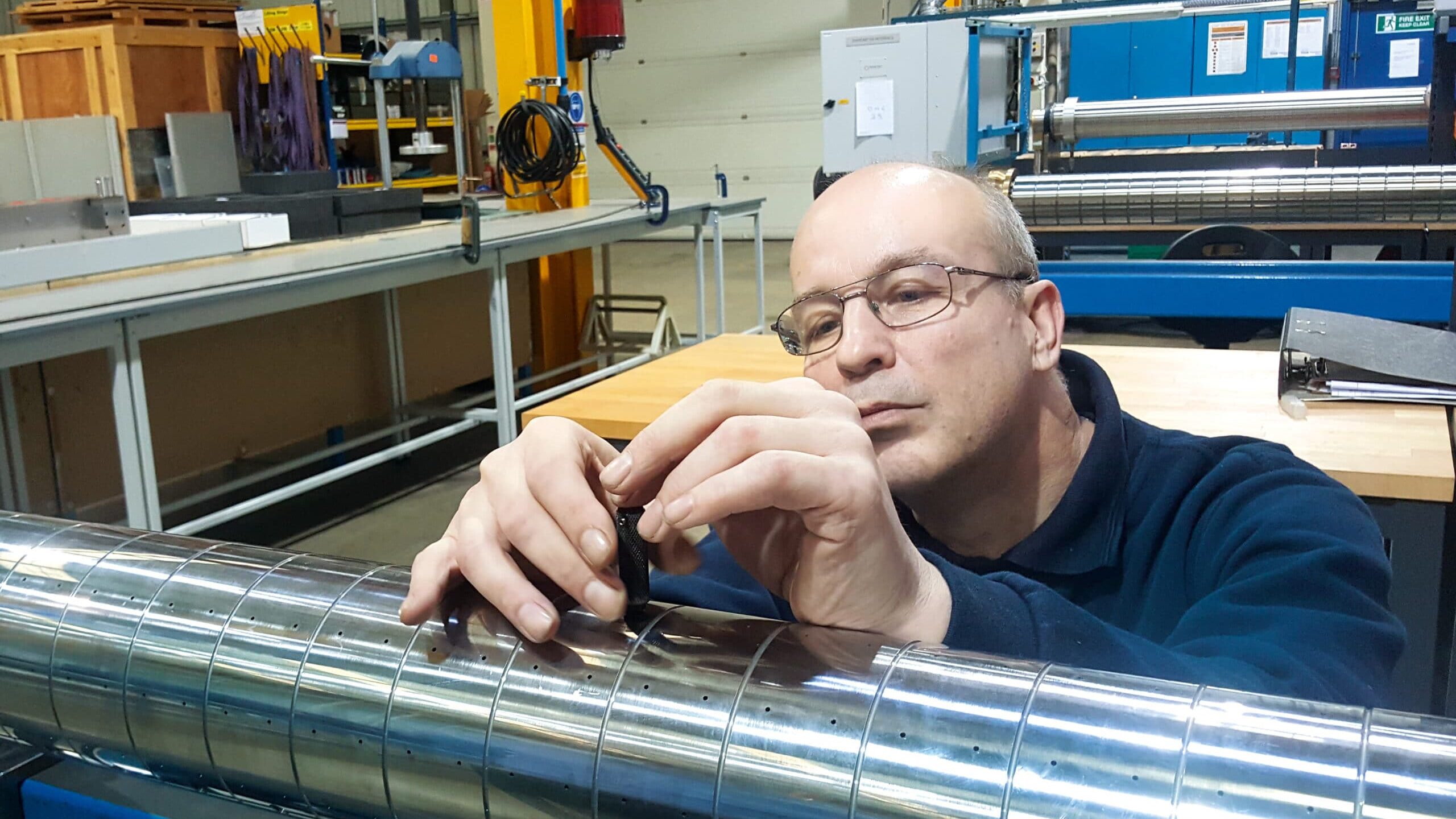

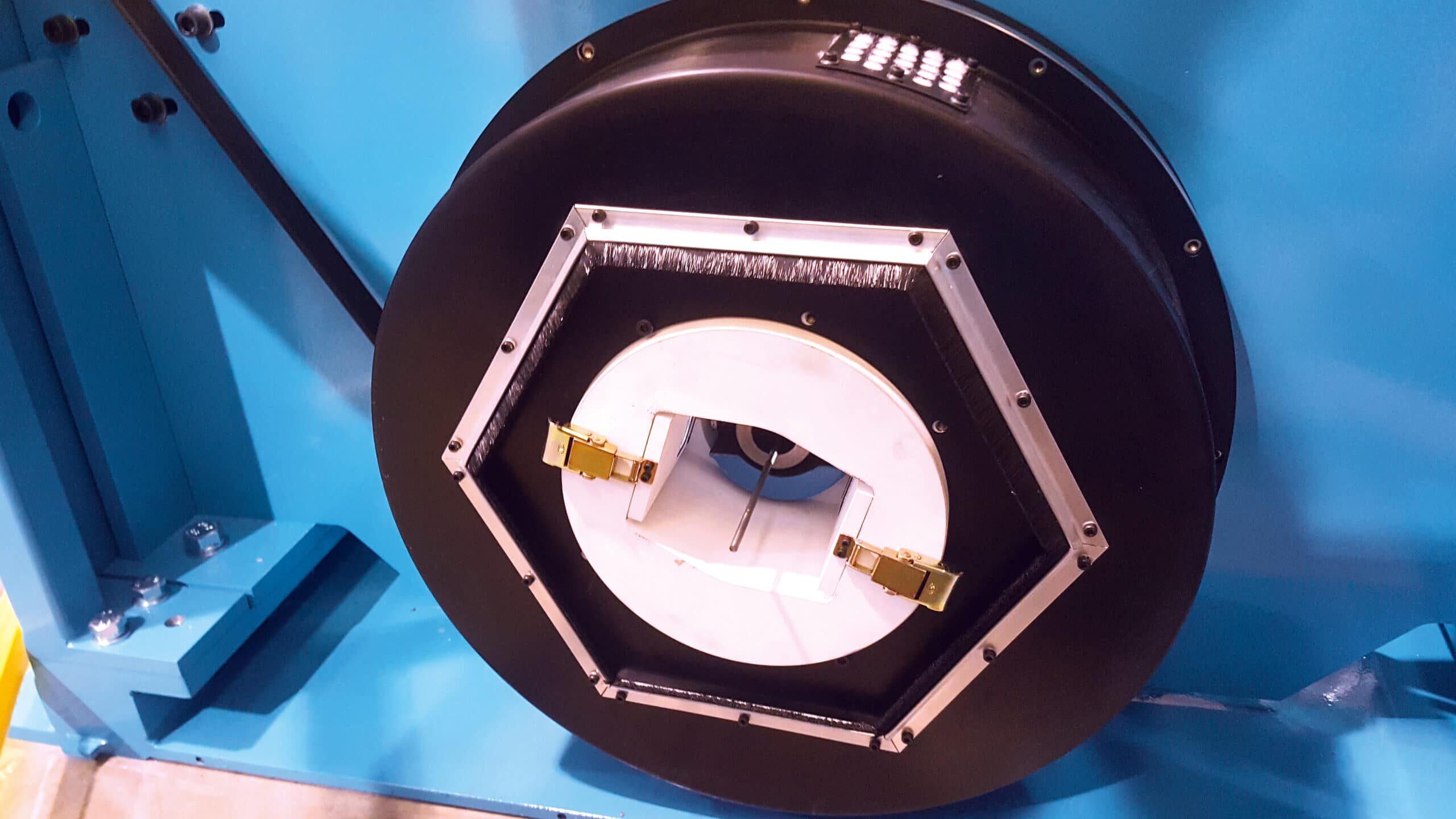

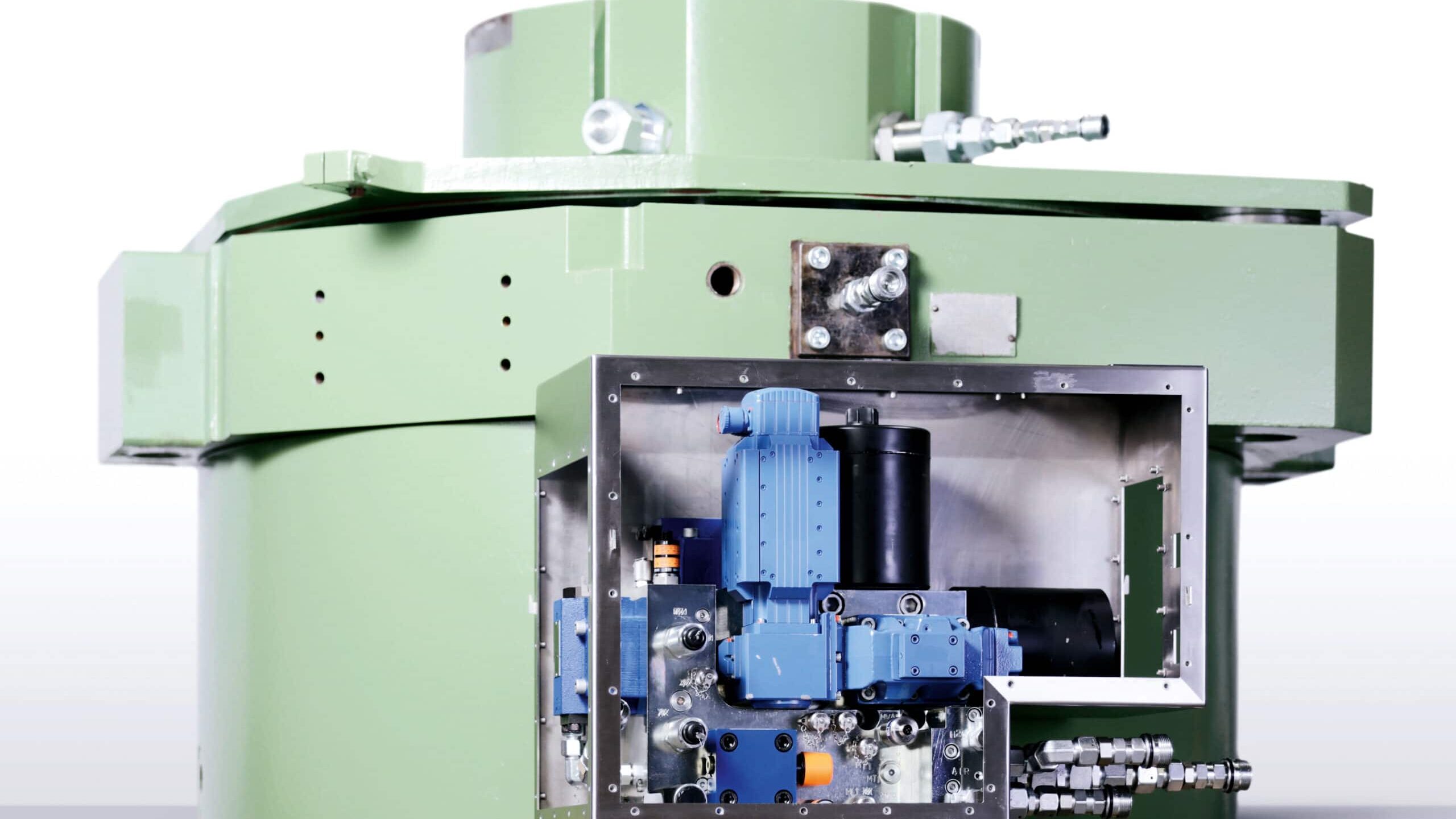

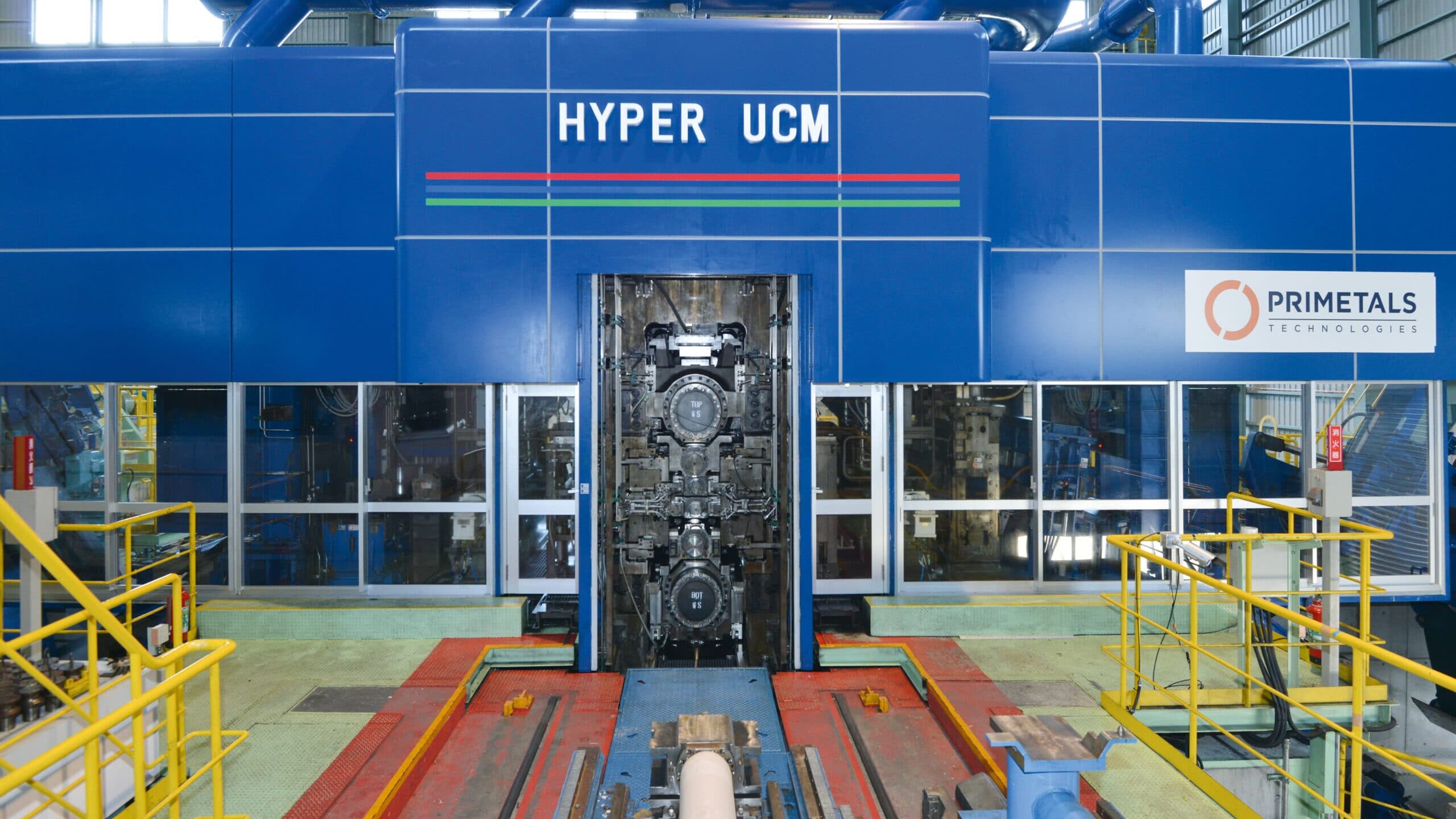

The Hiroshima location of Primetals Technologies features a workshop where a large variety of products for the steel

industry is engineered and manufactured.

Read moreChristchurch

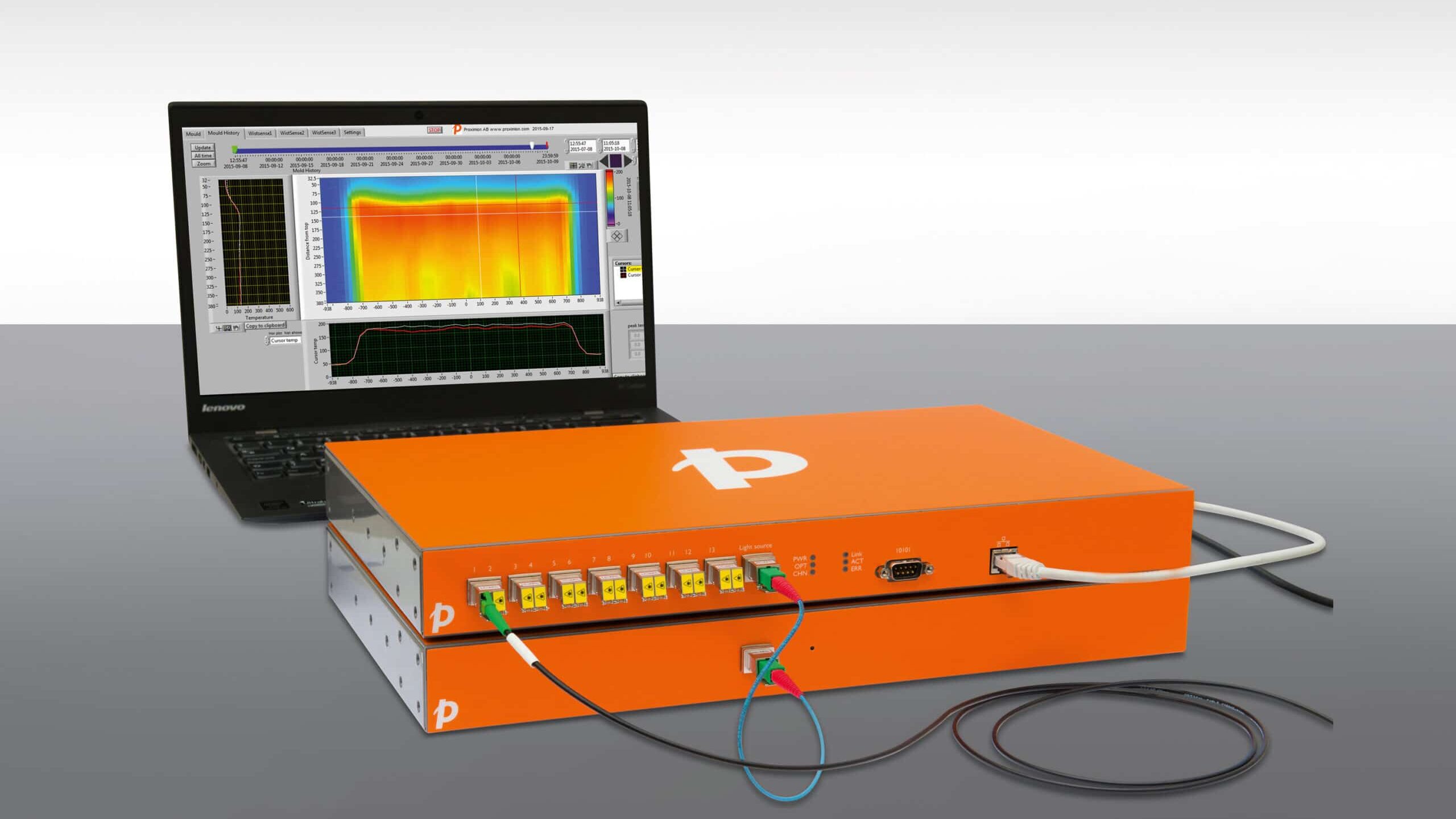

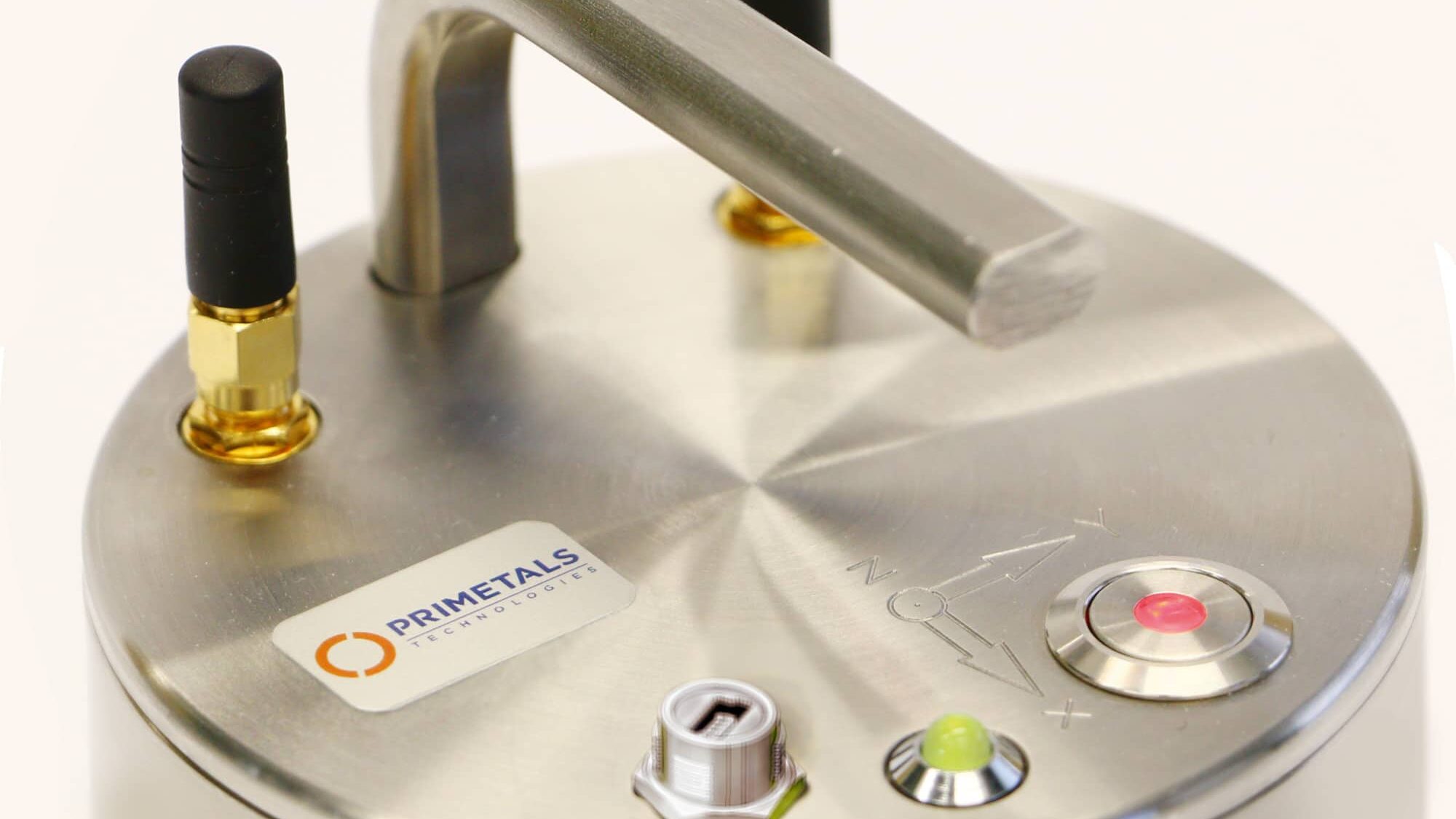

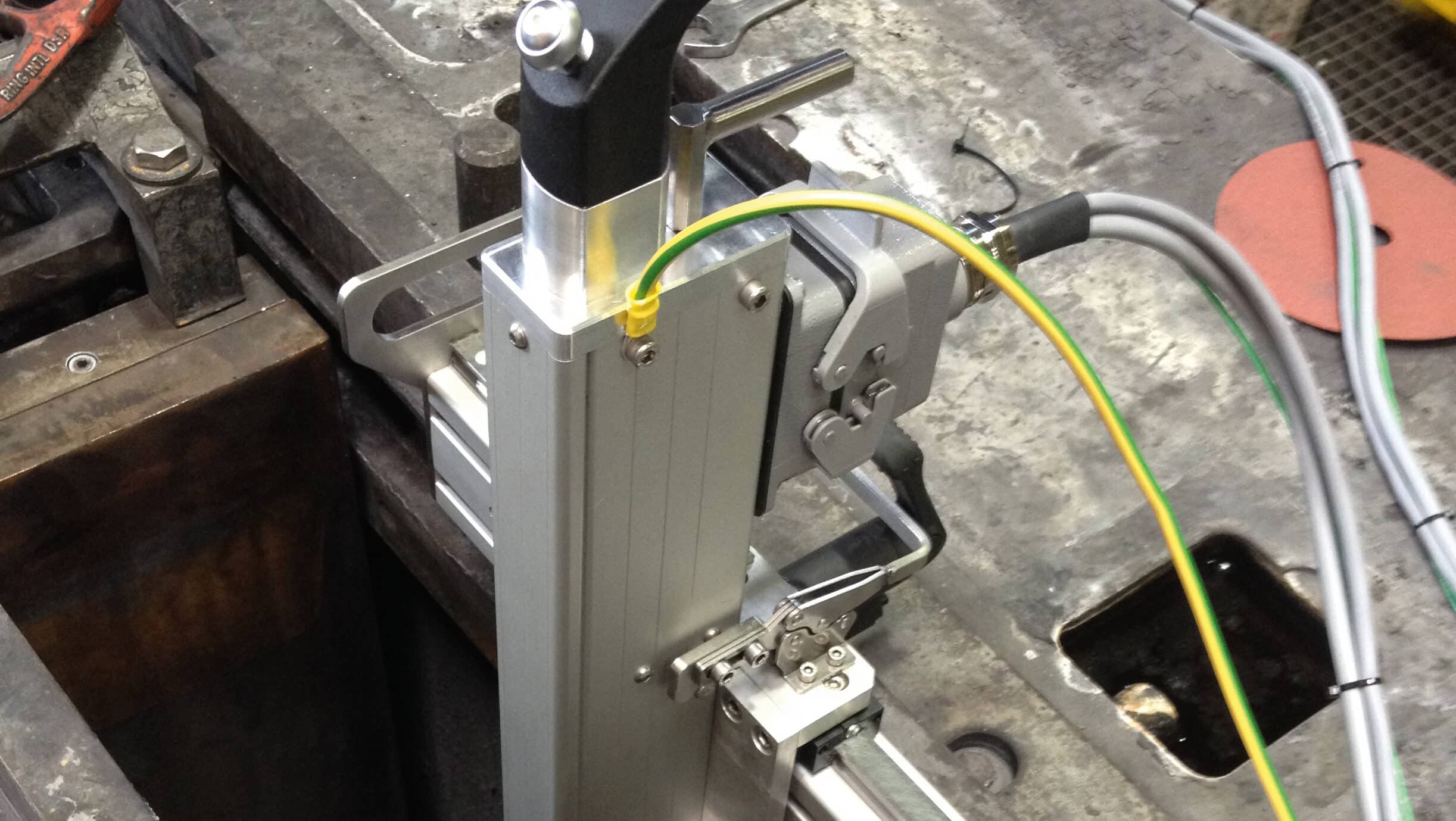

The company location in Christchurch, U.K., specializes in advanced sensor solutions for metals production.

Read moreMumbai

The company location in Mumbai, India, unites an on-site workshop and engineering competence with a focus

on components for metallurgical services

Read moreErlangen

The Erlangen company location of Primetals Technologies focuses on digital solutions for the downstream area in steel production.

Read moreApodaca

Primetals Technologies Mexico is located in Apodaca, which is part of the Monterrey metropolitan area

Read moreCracow

The Cracow company location specializes in plant automation software for the global metals industry

Read moreRio de Janeiro

Santa Cruz belongs to the West Zone of Rio de Janeiro, Brazil’s second-largest city and home of Samba music.

Read more Past Issues