This post is also available in: 简体中文 (Chinese (Simplified))

The extensive R&D efforts of Primetals Technologies are an integral part of the company’s larger strategy to continually promote innovation for the metals industry. In this series, we present new, remarkable solutions and services pioneered by Primetals Technologies’ engineers—solutions that may still be in their infancy today but have the potential to change the way steel and other metals will be produced in the decades ahead.

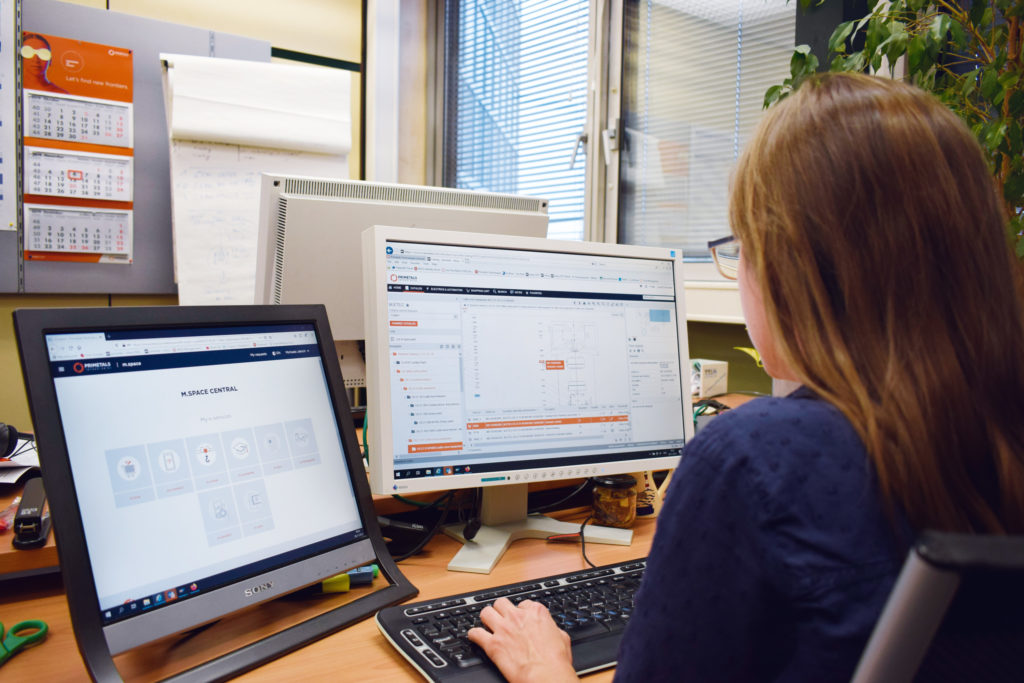

“Working with m.buy, I have learned to love data,” says Michaela Jaksch. m.buy is the new web-based spare-parts catalog from Primetals Technologies. Launched by the company’s Services organization under the umbrella of m.space, it contains vast amounts of data about every possible spare that a steel producer could need. “With m.buy, we want to make it easier than ever before for our customers to order the spare parts they need,” says Jaksch. “This is why we are customizing the m.buy catalog for each of our customers, so that they are presented exclusively with those spare parts that match the equipment they currently have installed.”

A SYSTEMATIC APPROACH

Jaksch uses a systematic approach when creating new spare-parts catalogs. Depending on a steel producer’s plant configuration, she first collects data on all potentially relevant spare parts. The accumulated data is then structured based on the layout of the plant. Here, one of m.buy’s nicer features comes into play: the entire plant is represented by schematics based on assembly drawings—not only of the overall plant but also of individual sections and smaller components. Every drawing contains references to the spare parts used by the equipment shown, and each part is labeled. For maintenance personnel who use m.buy, this means that they are given exactly the information they need, when they need it. No more time wasted on searching for the right spare part, hastily trying to ensure uninterrupted plant operation.

ENGINEERING OF THE FUTURE

Many of m.buy’s technological underpinnings are very much at the cutting edge. Jaksch is a regular contributor to the “Engineering of the Future” initiative at Primetals Technologies, which aims to incorporate innovative concepts into existing and upcoming solutions. She interfaces with colleagues working on augmented reality applications, information management, and artificial intelligence. This exchange helps to ensure that everyone is using the latest and most advanced techniques in the development of their solutions. m.buy also undergoes constant, rigorous testing with a lot of trial and error: “We try different approaches to make finding the right information as easy as possible,” says Jaksch. So what does the future hold for Jaksch and her work on m.buy? More data, more customers, more spare parts? Certainly. And, for the time being, more testing.