Innovative Solutions for Continuous Casting

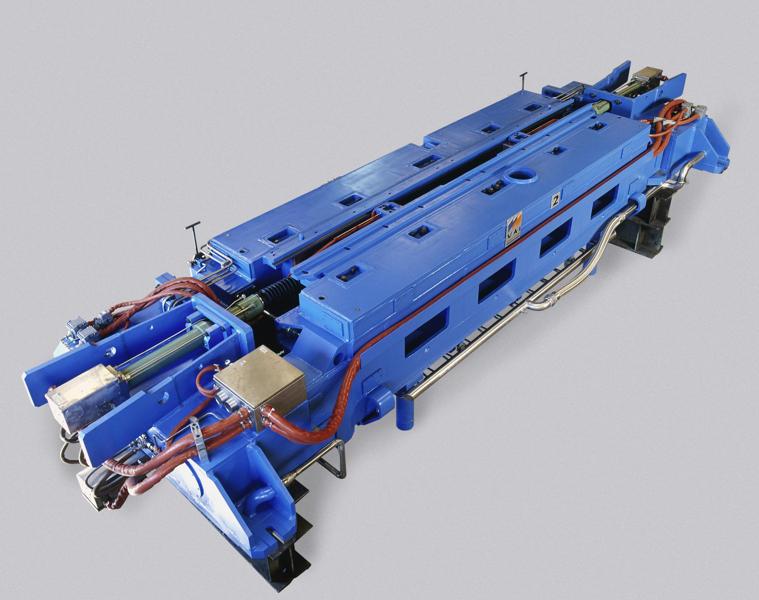

The Smart Mold is a high-performance cassette-type caster mold engineered to revolutionize continuous casting operations in the steel industry. Designed to address key challenges such as downtime, slab quality, and operational flexibility, the Smart Mold offers innovative solutions that enhance productivity and reduce costs. Its advanced features, including quick mold changes, hydraulic width adjustment, and automatic water coupling, make it an indispensable component in modern steel plants.

The Smart Mold is specifically designed to meet the stringent demands of modern steel production. Its cassette-type design allows for quick replacement of copper plates, significantly minimizing downtime and ensuring consistent production quality. The hydraulic mold width adjustment feature enables automatic and variable slab width changes without reducing casting speed, ensuring flexibility and efficiency in production. Straight copper plates are engineered to promote even shell growth, improve strand cleanliness, and simplify remachining and alignment checks, resulting in higher-quality slabs.

Additionally, the automatic water coupling system facilitates fast and seamless mold changes, reducing operational delays and enhancing productivity. The innovative grooved design of the foot rollers ensures automatic centering and efficient water connections, further improving reliability and operational performance. These advanced features collectively make the Smart Mold a critical tool for achieving high-quality, cost-effective, and flexible continuous casting.

Benefits of the Smart Mold

- Enhanced slab quality: achieves superior surface and internal slab quality through precise design of the highest stiffness and consistent mold performance

- Operational efficiency: quick and easy mold changes, supported by automatic water coupling, reduce downtime and boost productivity.

- Cost savings: the cassette-type design minimizes the need for operational spares and lowers maintenance costs.

- Flexibility: hydraulic mold width adjustment accommodates variable slab widths, meeting diverse production requirements.

- Improved cleanliness: straight copper plates ensure even shell growth and improved strand cleanliness, resulting in higher-quality end products.